A sophisticated automatic sanitary pad production line is a complex system designed to rapidly manufacture sanitary pads in large volumes. These lines typically involve several phases, each computer-controlled to ensure consistent uniformity. From the processing of raw materials to the final wrapping, every aspect is optimized for maximum efficiency.

The use of an automatic sanitary pad production line offers numerous benefits. It minimizes the need for manual labor, leading to reduced expenses. Furthermore, automation ensures accuracy in every step of the production, resulting in consistent product quality.

Automated Sanitary Napkin Manufacturing Equipment

The requirement for high-speed sanitary napkin manufacturing equipment has grown dramatically in recent years. This is due to the booming global market for feminine hygiene products and the need to meet this increasing demand. High-speed manufacturing equipment offers several benefits over traditional methods, including accelerated production times, refined product quality, and lowered labor costs.

These machines are typically computerized and can create a large number of napkins per hour. They often feature sophisticated technology, such as sensors, to guarantee consistent product quality and productivity.

The elements of high-speed sanitary napkin manufacturing equipment can be intricate and include systems for product transport, napkin shaping, adhesion application, and finishing. Manufacturers continually devote resources to innovation in this field, leading to the creation of even more optimized and trustworthy read more equipment.

Automated Pad Production System for Enhanced Hygienic Solutions

Modern sanitary pad machines offer an advanced approach to creating hygiene products. These automated systems enhance the entire production process, from raw material handling to the finished product. By utilizing robotic technologies, sanitary pad machines ensure high-speed production with reliable quality. This produces significant gains for manufacturers, including increased efficiency, reduced labor costs, and improved product consistency.

Moreover, sanitary pad machines often incorporate safety features to reduce workplace risks. This commitment to safety makes these machines a essential investment for companies in the hygiene product industry.

- Therefore, sanitary pad machines represent a important advancement in hygiene product creation, driving both productivity and safety within the manufacturing process.

Innovative Sanitary Pad Making Technology

The sanitary pad industry is progressing at an incredible pace. Modern manufacturing facilities are now utilizing sophisticated technology to produce pads that are highly absorbent, gentle, and eco-friendly. Automated machinery efficiently cuts, layers, and assembles pad components, ensuring consistency and quality. Additionally, these advanced systems often incorporate measuring tools to monitor production processes in real time, optimizing efficiency and minimizing waste.

- Computerized machinery is revolutionizing the sanitary pad manufacturing process, resulting in greater productivity and precision.

- Innovative systems are used to monitor production parameters, ensuring consistent product quality.

- Environmentally responsible components are increasingly being incorporated into pad manufacturing to decrease environmental impact.

Automated Sanitary Pad Assembly System

A cutting-edge automated sanitary pad assembly system is a groundbreaking solution designed to optimize the production process of feminine hygiene products. This sophisticated system utilizes cutting-edge technology to efficiently assemble sanitary pads with exceptional speed. The system's capabilities include meticulous component assembly, ensuring that each sanitary pad is reliably manufactured to meet the highest industry benchmarks. The automated nature of this system substantially lowers manual labor, resulting in increased production and minimized expenses. Furthermore, the robotic integration improves product consistency, ultimately providing consumers with a dependable product.

Cutting-Edge Sanitary Napkin Production Solutions

Sanitary napkin production is a highly specialized industry requiring state-of-the-art equipment and technology. To meet the ever-growing expectations of consumers, manufacturers are constantly seeking innovative solutions to enhance production processes.

Modern sanitary napkin production lines often employ automation and robotics to streamline assembly. This increases efficiency, reduces workforce costs, and promotes consistent product quality.

Furthermore, manufacturers are adopting sustainable practices throughout the production cycle. This includes using biodegradable materials, minimizing waste, and streamlining resource management.

These progressive approaches are shaping the future of sanitary napkin production, leading to higher quality products, reduced environmental impact, and greater market satisfaction.

Patrick Renna Then & Now!

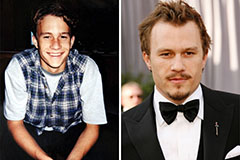

Patrick Renna Then & Now! Heath Ledger Then & Now!

Heath Ledger Then & Now! Jurnee Smollett Then & Now!

Jurnee Smollett Then & Now! Catherine Bach Then & Now!

Catherine Bach Then & Now! Christy Canyon Then & Now!

Christy Canyon Then & Now!